How to Ensure a Safe and Efficient Linen Chute Installation

A linen chute is an efficient method for quickly and economically disposing of soiled linen in multi-story hotels and hospitals. It allows fast and convenient collection from all floors, directing linens straight to the laundry room. This system reduces elevator use, saves time for housekeeping staff, and improves overall workflow. Linen chutes can be installed in any duct that is accessible from multiple floors, whether in commercial or residential buildings. If you’re considering a linen chute, search for a system that includes a chute door and offers convenient installation services near you.

The garbage chute, simply called the “Centralized Garbage Collection System,” besides providing an effective and hygienic way of disposing of rubbish, also improves the cleanliness and tidiness both in residential and commercial edifices. It is also helpful for easy disposal of rubbish for quick waste disposal in order to avoid clutter in any common area and maintain better sanitation. In the end, the garbage chute is very helpful in the effort to manage rubbish well. In addition, it has made the collection of wastes a seamless process that is easier to both residents and staff. That is further improved for better daily activities so that there can be an attractive area to stay or work. It also contributes to better sanitation that saves the time and efforts spent on waste management. At the end, it becomes healthier for staying or working environments. It also minimizes the risks of spilling, in addition to bringing about bad odour, making for a cleaner odorless environment for everyone.

Features of Linen Chutes:

- Manufactured & Installed as per BS 1703:2005, NFPA 82

- Manufactured in Austenitic Stainless Steel, Grade SS 304. Stainless steel 304 has the advantage of being resistant to the humidity, acid and alkalis contained within dirty Linen

- The intake doors have a 90-minute fire rating.

- Interlocking of intake door allows only one door to open at any given time and other door remains locked with busy indicated. This feature enhances the safety of the system.

- A standalone access control system can be provided

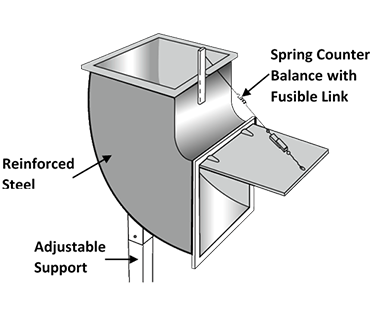

- Fire Cut off the door provides at the discharge end. The discharge end is D-type

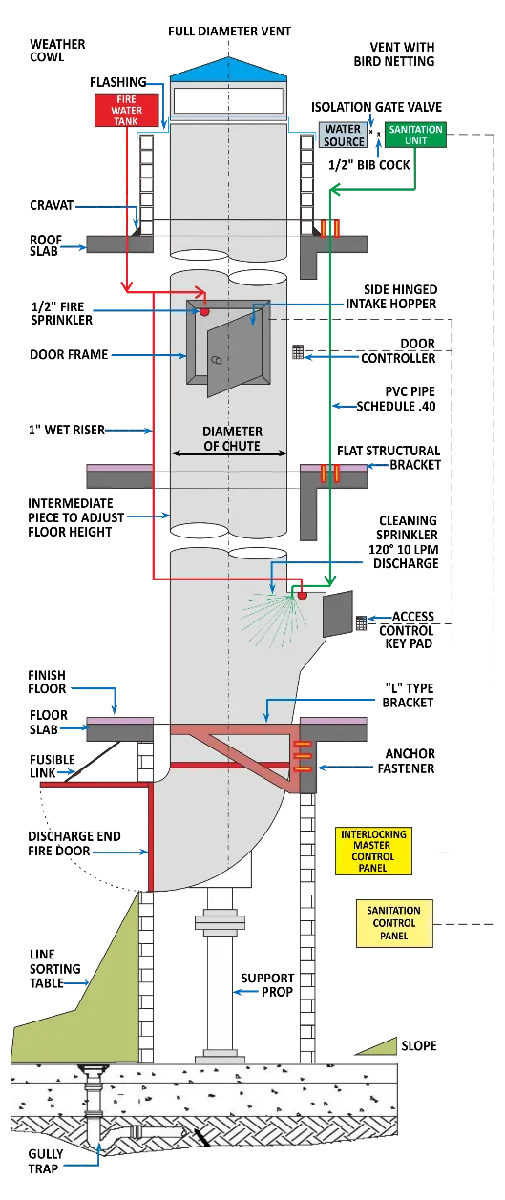

- A full-diameter air vent system allows air movement, which is necessary for vacuum breaking.

- A sanitation system provides for the internal cleaning of chutes.

- Fire Sprinklers are provided for fire safety.

TECHNICAL SPECIFICATIONS

Selection of chute diameter

Type of Building Linen Chute Dia.

- Residential 600 mm

- Hotel/Hospitals 750 mm

Hopper Size of the standard chute

Chute Diameter Hopper Size (Side Hung)

- 600mm, i.e. 24″ Typical Size 18″ X 18″

- Maximum Size 18″ X 21″

- 750mm, i.e. 30″ Typical Size 21″ X 21″

- Maximum Size 24″ X 24″

Material of Construction:

1. Manufacture with Stainless Steel as a base material (Grade SS 304, Thickness 1.5 to 2 mm)

2.BS/NFPA Codes prohibit fiber and plastic chutes because of fire hazards.

Intake Door

Intake doors feature side-hinged, manual-closing hopper-type designs.

The installation fixes linen intake doors with a chute in the front wall.

All the intake doors are provided with electric interlocks, stainless steel tee handles having self-latching, and keys to prevent unauthorized access to the linen chute door and to lock them tightly during maintenance. Additionally, all these features improve the overall safety and security of the system. In addition to this, the electric interlocks also provide an additional safety provision of keeping the chute closed whenever unused. This design minimizes the risk of accidents and unauthorized access; thus, it fosters a safer environment for staff and residents. The self-latching mechanisms ensure that the doors of the linen chute system automatically close, thereby creating more convenience and efficiency in day-to-day operations.

Intake doors carry a 90-minute fire rating.

The intake door has a Door controller with an “Open” Button and “Ready”, “Busy”, and “Fault” indicators.

Door interlocking allows only one user to use the chute at any given time.

Stand Alone Access Control (Optional)

A standalone access control system with a 12-digit keypad is provided near the intake hopper.

A four-digit resettable changeable password for each intake door will allow usage by authorized persons only.

A master password is provided to override any password.

Discharge

Linen Chute is provided with a “D Type” discharge door.

The system is designed to divert the linen from the chute duct into the linen room at the desired height.

It consists of a fire cut-off door with a latch to close the chute in case of an eventuality. Additionally, this feature enhances safety by preventing the spread of fire and smoke through the chute, ensuring a more secure environment for occupants.

This door connects to 174-degree F fusible links, which melt in the event of a fire. As a result, the door closes automatically, effectively sealing off the chute. Consequently, this mechanism helps contain the fire and prevents smoke and harmful gases from spreading throughout the building. Moreover, it enhances overall safety by protecting both residents and staff while simultaneously minimizing potential damage and supporting fire safety protocols.

Air Vent:

It enables the breaking vacuum created by falling Linen.

It provides a weather cowl & bird screen.

Fire Sprinklers

Install auto fire sprinklers on the topmost and bottommost floors and on every alternate floor.

It starts automatically at 68 degrees C. to extinguish the fire

½” IPS (BSP) female threading ready to be connected to 1″ wet riser of fire protection system is provided.

Provisions required for installation of Linen Chute

Duct Size

Chute Diameter Duct / Slab Opening

- 600mm, i.e. 24″ 32″ X 32″

- 750mm, i.e. 30″ 36″ X 36″

- For other sizes, Dia of Chute + 8.”

Looking for Linen chute Installation then you reach at correct place.